Institute TOMS in collaboration with LITS company successfully commissioned a wet high intensity magnetic separator (WHIMS). After our specialists сompleted the training, TOMS laboratory was accredited to run test works using this equipment.

In October 2025, Institute TOMS in cooperation with FINGRI company successfully commissioned a pilot vertical mill for fine grinding testworks.

Design works

Design of mining and processing facilities and infrastructure is one of the core activities of Institute TOMS.

Institute’s specialists carries out design works and elaborate design documentation for greenfield construction, renewal and retrofitting projects for the following metal ore mining and processing facilities:

- hazardous and highly hazardous industrial facilities such as processing plants, gold plants, mining and processing complexes, heap leaching plants, crushing and sorting complexes, hydraulic structures including tailing ponds;

- infrastructure facilities: power supply utilities including main step-down substations, package transformer substations, power transmission lines and others; water supply and disposal facilities such as water intake and discharge plants, waste disposal works, water treatment plants; heating, venting and conditioning facilities including boilerhouse; other utility systems (communication networks, compressed air and gas lines); storage facilities, including chemical and hazardous chemical stores, concentrate store media store, fuel and lubricant storage, commodities and materials storage; laboratory facilities, e.g. assay and fire assay laboratories, technical control division; mechanical repair shops; permanent accommodation and offices; facilities for mine rescue and fire brigades; shift camps; indoor and outdoor pipelines and networks; and other facilities required to ensure functioning of a plant.

Institute TOMS develops all types of design documentation in compliance with relevant valid regulatory documents (Decrees of the Government of the Russian Federation, Orders of the Ministry of Natural Resources and Environment, federal laws, Russian State Standards (GOSTs), Russian Construction Rules and Regulations (SNiPs), and other documents regulating requirements to design of ore mining facilities):

- design philosophy for implementation of a processing plant project, i.e. main design solutions and main technical/process solutions with comparison of process flowsheet options, PFDs, layout solutions, as well as scoping and trade-off studies;

- different types of studies to check feasibility: FS, PFS, BFS;

- basic design documentation for greenfield projects;

- basic design documentation for reconstruction projects;

- detailed documentation to construct mining and processing facilities;

- design sudy for primary mineral processing;

- retrofitting of hazardous facilities;

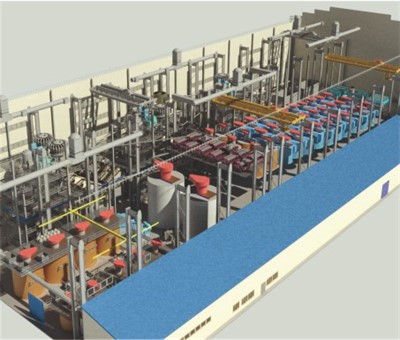

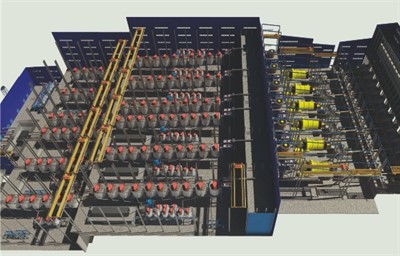

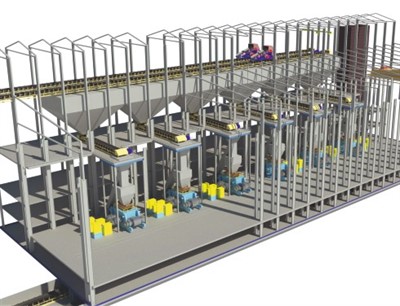

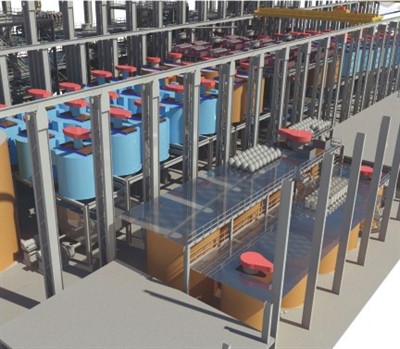

- informational 3D, 4D, and 5D models of a facility with minimum LOD 300, and LOD 400 for the process solutions part;

- presentation graphics, drawings, and animated images for existing facilities and facilities under design.

Application of BIM technology as a key work tool for elaboration of 3D information models of a plant being designed allows considerable amount of work of any complexity to be performed in the shortest time possible and at a high quality of design deliverables.

Institute TOMS guides the developed design documentation through the relevant expert reviews until the receipt of an affirmative expert report:

- basic design documentation for hazardous industrial facilities must be submitted for appraisal to:

- the Federal Service for Supervision of Natural Resources to undergo the state ecological appraisal; and

- the Federal Autonomous Institution “Main Department of State Expertise”;

- detailed design and front end engineering design documentation is not subject to any expert appraisals but must be approved by a client directly;

- design study for primary mineral processing needs to be approved by the Central Commission on development of solid mineral deposits of the Federal Agency for Mineral Resources;

- documentation for technical retrofitting must be submitted for an expert appraisal of industrial safety to a properly licensed.

Institute TOMS provides qualified design supervision for a facility construction period.

Examples of completed projects