Institute TOMS in collaboration with LITS company successfully commissioned a wet high intensity magnetic separator (WHIMS). After our specialists сompleted the training, TOMS laboratory was accredited to run test works using this equipment.

In October 2025, Institute TOMS in cooperation with FINGRI company successfully commissioned a pilot vertical mill for fine grinding testworks.

News

The higher grade iron concentrate production process developed with extensive involvement of Institute TOMS was awarded the Russian Federation Government Prize in Science and Technology

The process for producing higher grade iron ore concentrate at Mikhailovsky GOK received the highest recognition – in December 2025, the team of specialists who developed and implemented this technology was awarded the Russian Federation Government Prize in Science and Technology, an annual award given for advances that have a significant impact on the development of the national economy, industry, and environmental protection.

Along with Metalloinvest, Mikhailovsky GOK, and MISIS Mining Institute the award was also given to Institute TOMS represented by its CEO, Arkady Senchenko.

At the awards ceremony, Russian Prime Minister, Mikhail Mishustin, emphasized the enormous role of the companies' work teams involved in developing this unique technology, who ultimately made a significant contribution to strengthening the global market position of Russia.

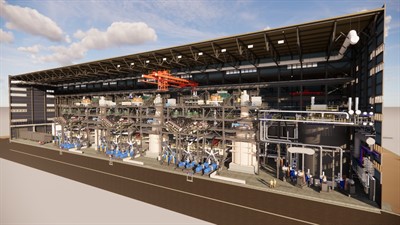

The scope of work completed by Institute TOMS as part of the construction of the Mikhailovsky GOK concentrate refining facility included comprehensive test works, process design criteria, basic design documentation with relevant expert reviews, detailed design documentation, and field supervision.

The new combined process flowsheet integrates fine screening, regrinding, and reverse cation flotation making it possible to process even complex refractory ore and produce higher grade concentrate where iron content can be flexibly adjusted from 67% to a record-breaking value of 71% with simultaneous reduction of silicon dioxide proportion. This premium quality concentrate enables the production of commercial DR-grade pellets which are the raw material for direct reduced iron.

The proposed technology, having been successfully implemented, has proven its effectiveness both in terms of production and economic performance as well as in terms of expanding the resource portfolio and reducing environmental impact.

Institute TOMS is proud be part of this audacious project and to have the importance of its contribution recognized at the government level.

This material was prepared using the press release and photographs from the official Metalloinvest website: https://www.metalloinvest.com/media/press-releases/1079870/.